post your thoughts to the discussion board about the pros and cons that Honda is using and an explanation about why

Statistical Process Control-Honda Discussion

Please watch the following video and post your thoughts to the discussion board about the pros and cons that Honda is using and an explanation about why. Also, add your thoughts about how things might be added or deleted to the process. Make sure to comment on 3 of your classmates suggestions and I will summarize my thoughts to your responses at the end of the week.

Statistical process control is a set of practices and procedures that are used in the manufacturing industry to monitor the quality of the products and get the quality management system in action (Doty, 1996). Honda also use statistical process control to make improvements to their manufacturing processes.

Pros: It is considerably simple process and helps a lot in understanding the failure rates regarding specific process. These statistics regarding the failure rates can then be used to make future adjustments.

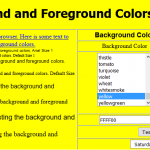

To monitor process capability, Honda uses SPC charts and histograms. They have their pros and cons. The advantage is that it is a timely, accurate representation of the data that has been collected by different computers. It helps in identifying irregularities within the industrial processes. These charts help in getting the industrial processes in accordance to the industrial standards by regularly monitoring them.

Cons: All the data that is collected from different tests at Honda is added to the data mine. There are always concerns about the security of data mines and I believe that Honda would need special arrangements to safeguard data from external attackers.

The disadvantage of the SPC charts and histograms is that they should not be monitored and interpreted by just any employ at the Honda plant. Wrong interpretations can lead to extra time being used on rectifying something that was wrongly interpreted.

What can be deleted and what can be added:

The door closing test can be performed with the help specialized robots hence minimizing the time and human resource required to perform the task.

The SPS charts that are monitored by Humans might be too late in some manufacturing process. Therefore Honda might want to organize a computerized system that can send alarms if some process cross the thresholds allocated to them as this happens.

References

Doty, L. A. (1996). Statistical process control. Industrial Press Inc.